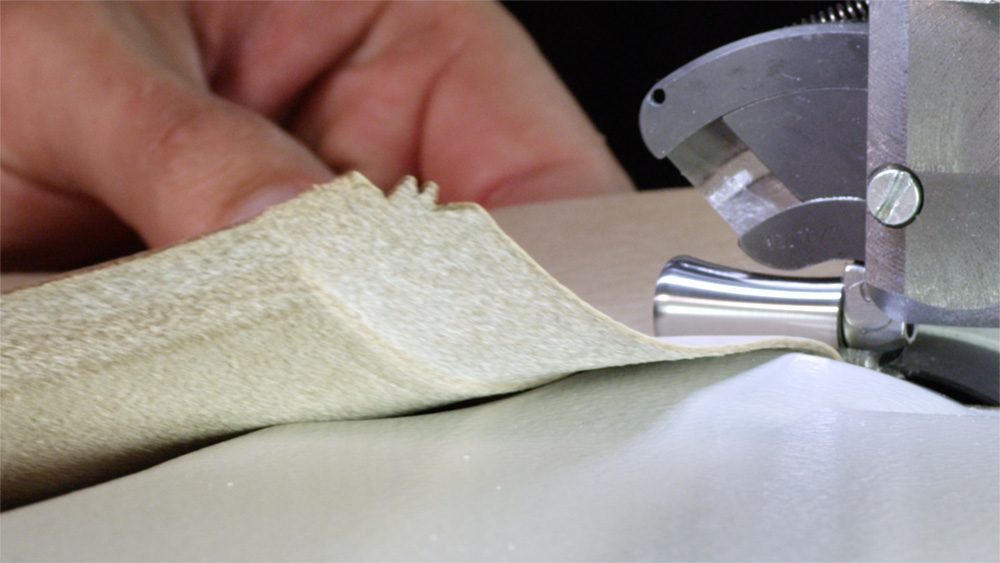

SKIVING MACHINE

Various materials in any shape and size are split into different layers with greatest precision.

Through this splitting process, uneven materials can be brought to uniform thickness, or the initial thickness reduced to a final measure.

Incision splitting is one of numerous options that can be applied. In contrast to skiving, not only the outer edge is reduced, but the whole of the material.

The endless band knife allows a permanent sharpening during the process.

Through the use of profile rolls, profile bars and templates, different indentations can be made in the material.

A continuous, solid cast iron body guarantees operation with low vibration, even after years of use.![]()

Our machines's ergonomics are characterised by a continuous work surface, easy access of the operating module, and a targeted illumination of the work area.

The possibility for roll-under machines enables flexible transportation and positioning.

Custom-fit original parts guarantee exact splitting for highest demands.

Lowest tolerances ensure best results.

Shoes| Leather goods | Automotive | Rubber | Automotive suppliers | Synthetic material | Cables

Paper | Cardboard | Recycling | Carpet | Felt | Sporting goods

| Type | Skiving width | Skiving angle |

Typical applications | Features |

| 34 S-AG/M | 0 - 11 mm | 0 - 45° | Moccasins | Driven guide roll |

| 34 VK | 0 - 34 mm | 0 - 20° | Shoe caps, thermoplastic and uncoated materials in high volume | Driven guide roll |

| 50 KK-S | 0 - 50 mm | 0 - 20° | Leather soles, hard and heavy materials, leather toe caps and counters | Driven guide roll |

| 50 KS-G | 0 - 50 mm | 0 - 20° | Plastics, rubber, printing blankets, diving suits, technical foams, conveyor belts | Driven guide roll |

| 50 KT-SA | 0 - 50 mm | 0 - 20° | Artificial fur, natural fur, felt | Driven guide roll |

| ES 50 | 0 - 50 mm | 0- 20° | Shoes, leather goods, belts, technical textiles, laminated materials in low volume | |

| NG 3 | 0 - 18 mm | 0 - 33° | Shoes, leather goods, belts, laminated materials | Manually adjustable grinding and knife positioning |

| NG 6 | 0 - 18 mm | 0 - 33° | Steering wheels, seats, gear knobs, door panels | Automatic grinding and knife positioning |

| V 34 S/KF | 0 - 34 mm | 0 - 20° | Shoe caps, thermoplastic and uncoated materials in low volume | Driven guide roll |

| SM 50 | 0 - 50 mm | 0 - 20° | Shoes, leather goods, belts, technical textiles, laminated materials in low volume | Without working table and suction |

Changes are also possible without prior notice